Benefits:

– Provide strong, stable support for the PCB throughout the wave solder process

– Permit wave solder processing of through-hole components while masking solder-side SMT components and critical board features from molten solder

– Provide thermal protection for printed circuit board areas that are heat sensitive

– Allow processing of odd-shaped PCB’s through conveyor system

– Prevent topside component movement throughout wave solder

– Align and position topside components throughout wave solder

– Increase assembly production by eliminating hand gluing and masking operations

– Ensure higher quality, repeatable process results

– Reduce bridging and skipping solder defects

– Provide safe, easy, ergonomic handling of PCB

Features:

– Pallet design keeps bottom of circuit board coplanar with the conveyor

– ESD composite construction protects sensitive components by providing controlled static discharge

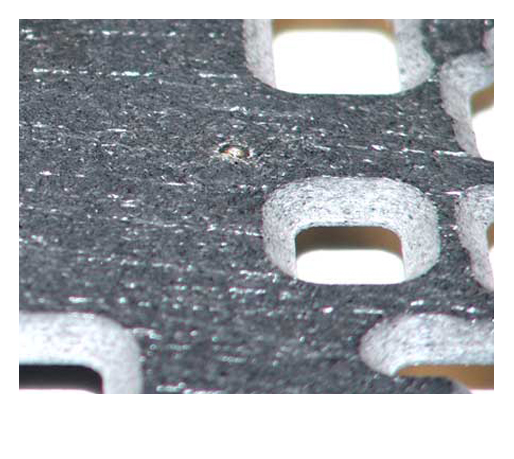

– Maximum possible “Knife Edge” beveling of fixture openings, provides the best possible solder flow to component leads

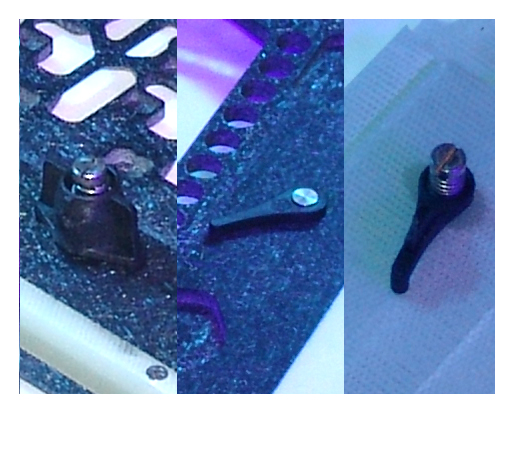

– Ergonomic PCB and component holddowns

– Wave Pockets and Solder Channels

promote better solder flow

– Free PCB pocket covers provided with multi-up fixtures