Benefits:

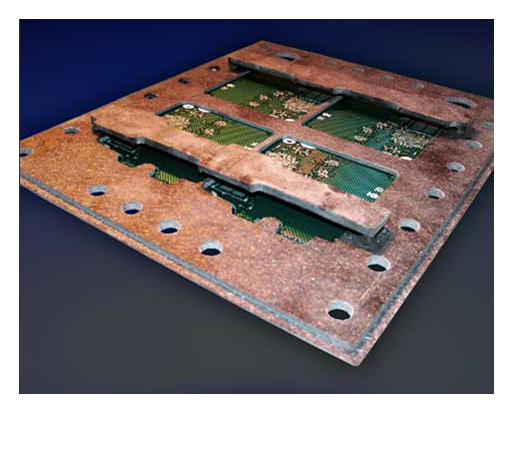

– Accurate, repeatable location of PCB

– Required for rigid-flex and flex circuit processing

– Process odd-shaped PCB’s

– Process PCB’s that are too thick for conveyors

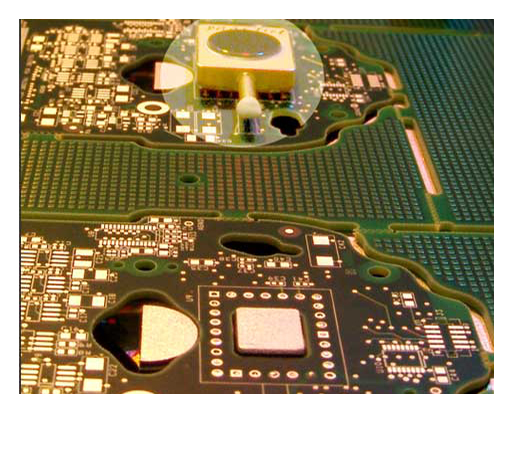

– Process PCB’s with components close to the edge of the board

– Protect bottom side components from double-sided reflow

– Prevent distortion and support the board through printing, placement and reflow without operator intervention

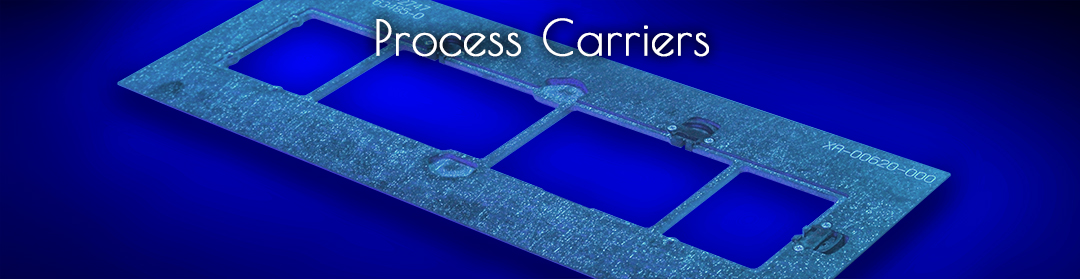

Features:

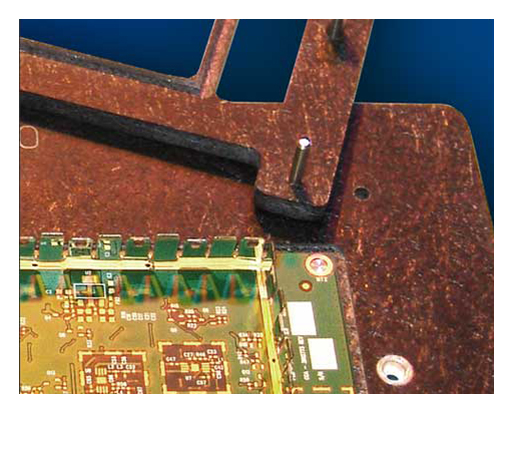

– Flush-mounted PCB holddowns

– Reduced thermal mass for process transparency

– ESD composite construction

– Finger slots for easy PCB loading and unloading

Options & Accessories:

– Overhanging component alignment features

– Reflective paint for optical sensitivity

– Topside holddowns for reflow of RF fencing

– Features for spacing components off the PCB during reflow

– OverArm Bars for holding down topside components through reflow

– Features for securing bottomside components during reflow